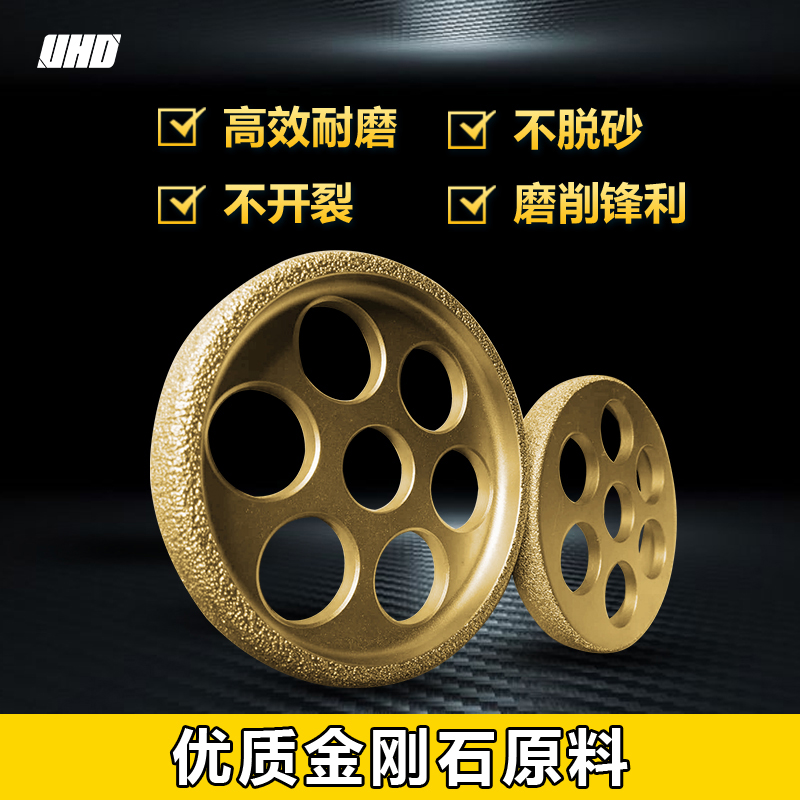

With the continuous advancement of science and technology, advanced vacuum brazing technology has shown excellent application potential in the field of metal processing. Especially in the manufacturing of 400-brazed diamond grinding wheels, the introduction of this technology means a major technological breakthrough in the industry.

The advantage of vacuum brazing technology is that it can combine metals in an oxygen-free environment, minimizing oxidation, thereby significantly improving the performance and durability of welded joints. This provides essential technical support for the development of diamond grinding wheels, allowing the products to maintain excellent performance in high-temperature and high-pressure environments.

In addition, with the precise control of advanced vacuum brazing, higher production efficiency and lower scrap rates can be achieved. This not only improves resource utilization, but also brings considerable economic benefits to enterprises, helping the industry move towards intelligence and automation.

Against this background, various metal processing companies should actively explore the application of vacuum brazing technology, seize this technological dividend, and improve their competitiveness to cope with changing market demands.

Are you further interested in the application of advanced vacuum brazing technology? Welcome to contact us to discuss the future of the industry together!