With the continuous development of science and technology, vacuum brazing technology has gradually become an important innovation in the stone processing industry. This technology not only improves production efficiency, but also significantly improves product quality, becoming a key factor for enterprises to enhance their competitiveness.

The application of vacuum brazing technology optimizes the processing process and reduces material waste. Through the improvement of heat conduction efficiency, the time for stone cutting and polishing is significantly shortened, thereby improving the overall production efficiency, which is particularly important for large-scale production.

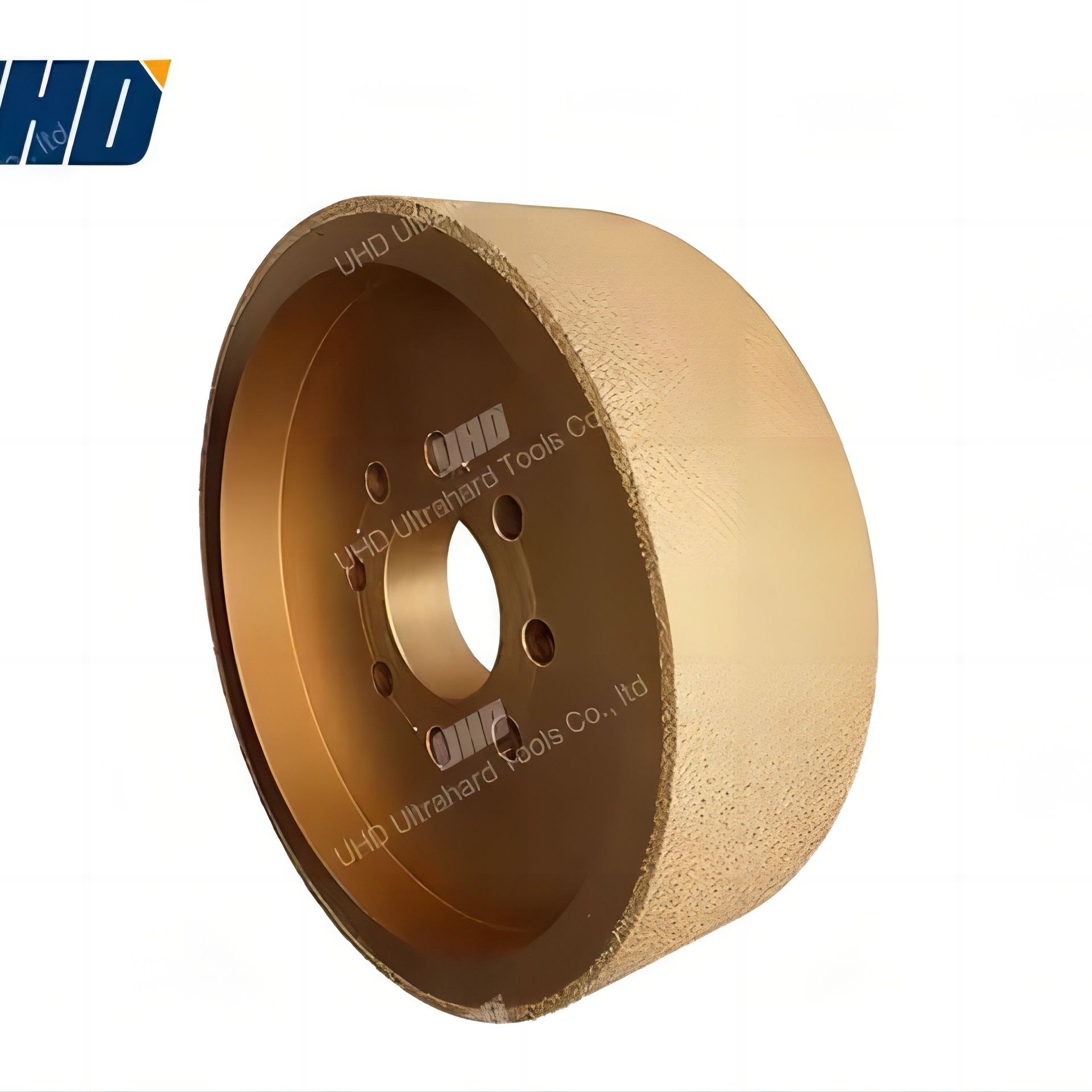

This technology also effectively improves the cutting accuracy and surface finish of stone. Processing in a vacuum environment avoids oxidation and pollution, ensuring a more stable quality of finished products and meeting the needs of the high-end market.

It is expected that as the technology continues to mature, vacuum brazing technology will be widely used in more stone processing links, and will promote revolutionary changes in the industry in the future. At the same time, companies that invest in advanced equipment will gain higher market share.

We welcome companies and experts in the industry to share their insights on vacuum brazing technology with us. You can leave a message below or contact our professional team to discuss the future development of the stone processing industry!